SMD REWORK STATIONS

SMD(Surface Mounted) Rework station is used to remove, replace, do re-balling BGA(Ball Grid Alley) chips and SMD components.

Make sure that the re-balling station are controllable and match to standard temperature for PCB's and SMD Electronic Components..

It is made of high quality heating material. desoldering and soldering of BGA's are precisely controlled.

Air flow and and Temperature are adjustable in wide range to produce high temperature breeze.

Movable and Replaceable heating heads and very easy to operate...

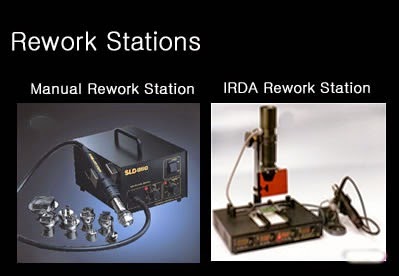

In the market today there are two types of rework station to choose that match your needs and budget.

The Oldest type is the Standard Filament Type Rework Station and the latest is called Infrared or IRDA Rework Station.

The Standard Type is Consist of a heating filament which is by then blowned by an air to produce a very hot air temperature.

A technical view of an SMD Rework Station with filament and an air blowing to produce hot temperature air flow...

Thermostat adjustment is applied by controlling the heat temperature and the amount of air to flow.

Some types of Filament SMD Rework Station are digital in which the amount of heat and air were displayed on a seven segment LED and a push button adjustment were placed.

Infrared or IR SMD Rework Station

This one was designed by an Infrared (IR) Technology.Uses infrared heat wave technology instead of the conventional hot air, effectively solves the major problem being encountered when using the hot air gun, which is the movement of surrounding components while reworking.

The small amount of Infrared light is amplified to produce a very high temperature Lazer Beam. It is digitally designed and can be set automatically.

A simple overview of an IR SMD Rework Station.

A set example of an IR SMD rework Station. Note: the Author is not endorsing any product.

Make sure that the re-balling station are controllable and match to standard temperature for PCB's and SMD Electronic Components..

It is made of high quality heating material. desoldering and soldering of BGA's are precisely controlled.

Air flow and and Temperature are adjustable in wide range to produce high temperature breeze.

Movable and Replaceable heating heads and very easy to operate...

In the market today there are two types of rework station to choose that match your needs and budget.

The Oldest type is the Standard Filament Type Rework Station and the latest is called Infrared or IRDA Rework Station.

The Standard Type is Consist of a heating filament which is by then blowned by an air to produce a very hot air temperature.

A technical view of an SMD Rework Station with filament and an air blowing to produce hot temperature air flow...

Thermostat adjustment is applied by controlling the heat temperature and the amount of air to flow.

Some types of Filament SMD Rework Station are digital in which the amount of heat and air were displayed on a seven segment LED and a push button adjustment were placed.

Infrared or IR SMD Rework Station

This one was designed by an Infrared (IR) Technology.Uses infrared heat wave technology instead of the conventional hot air, effectively solves the major problem being encountered when using the hot air gun, which is the movement of surrounding components while reworking.

The small amount of Infrared light is amplified to produce a very high temperature Lazer Beam. It is digitally designed and can be set automatically.

A simple overview of an IR SMD Rework Station.

A set example of an IR SMD rework Station. Note: the Author is not endorsing any product.

No comments:

Post a Comment